Better safe than sorry

Camembert, Roquefort cheese, and salami: Mold Fungi are commonly known as ways to refine certain foods. But not always – in fact in most cases – mold is definitely dangerous to the human body. Almost any kind of food can get affected: Mold spores are transported by air circulation and lay down on suitable surfaces where they sprout into the food. Different from the main conception, those fine threads (hyphae) are not only roots but the fungus itself. Having this in mind, it becomes clear that contaminated food cannot be correctly spotted by the bare eye.

Food Safety in the Industry

This does not only apply to the private fridge but also to food production. In the industry, food safety is more important than ever. Realistically, it’s not always possible to check every single product manually on the numerous pallets going through the process, although human sensory panels are the most common method of detection right now. Since the reputation of the producer and the health of the consumer are so highly affected, a more secure and objective way to ensure food safety has to be found.

As commonly known, during its rotting process, food emits specific odors which of course can be sensed by the human nose to a certain point. But those released compounds can be used even more effectively …

A smart solution

Based on its innovative ionization technology SICRIT®, Plasmion developed a powerful and sensitive sensory solution to fulfill this need for safety.

The volatile organic components of the products or, simply put, the odor can be analyzed directly in the process for exceeding certain trace limits by the HaVoc® Sensory System. This enables checking every single product individually and within seconds before goods are dispatched or received to ensure efficient inline-quality monitoring. The effort of laboratory tests is eliminated and precise evaluations appear in real-time. In addition, the quality controls are automated and thus represent an objective and reproducible data basis.

That way food analysis, which depends on modern technological solutions, is revolutionized.

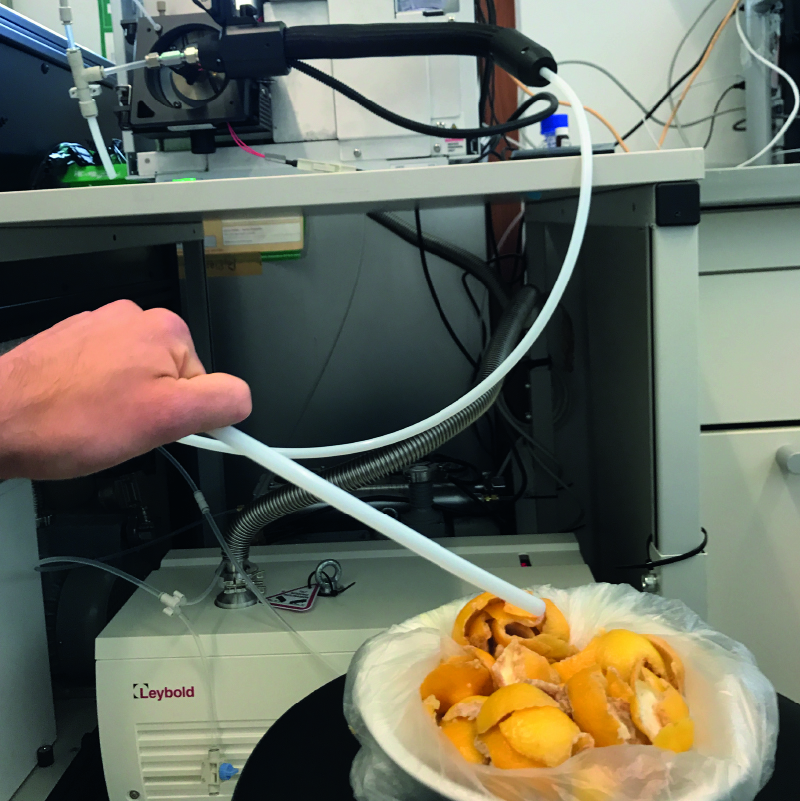

Demo: Analysis of lemon peel by the HaVoc® Sensory System

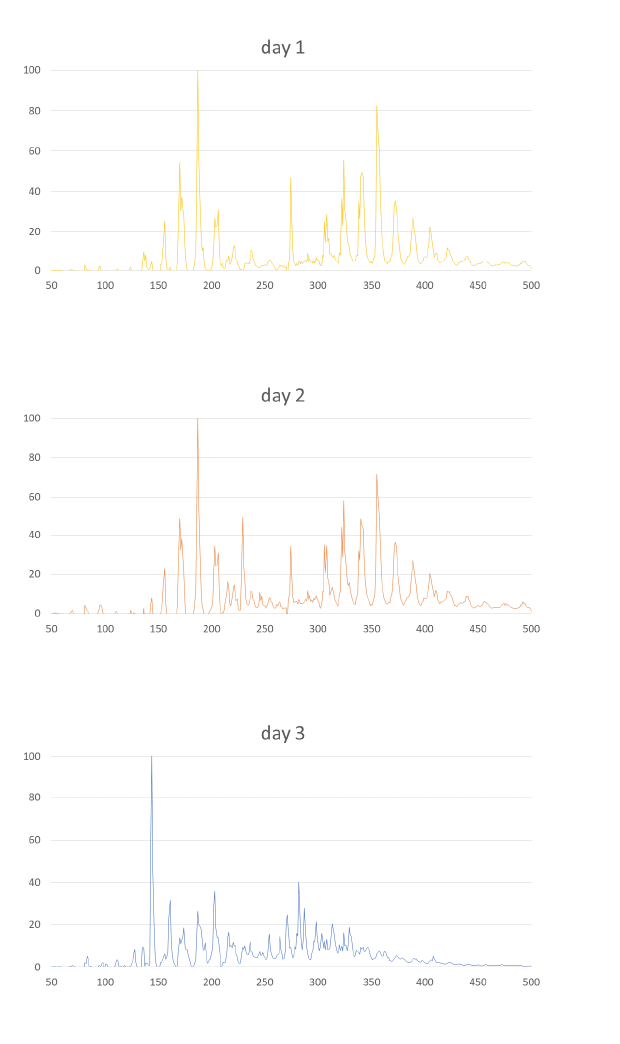

To demonstrate this solution for food safety, lemon peel was analyzed during its rotting process. For that purpose, peeled fresh lemon samples were stored in a closed plastic wrapping and the emitted volatiles were analyzed daily using an unboxed HaVoc® setup. The sampling was performed by a sampling tube (see picture below).

The results show that rotting leads to changes in the volatile profile emitted by the lemon peel. The HaVoc® Sensory System is able to detect significant changes in the volatile profile after three days.

In practice, this shows, how reliable and comparable results in food quality assessments can be ensured, such as monitoring fruits as shown in this example, thanks to objective and detailed data. Rotten batches can be spotted during food production which can ensure quality and protect consumers.

Intrigued by this sensitive and simplifying solution for the food industry? Learn more about the HaVoc® Sensory System, its technology, and use cases on our website or contact us for further information.