Food

Industry

In the food industry, customer trust and satisfaction are crucial, and there is a growing awareness of food quality and regionality. The industry is under pressure to meet zero failure tolerance and maintain transparency. Industry 4.0 technologies such as automated analysis of volatile organic compounds (VOCs) and in-line process control through industrial sensory systems offer advanced solutions to current challenges like food safety, food fraud, and food design.

Watch our brandvideo or contact us to learn how our solutions can help your industry.

Food Safety:

- Identify undesired residues or contaminations.

- Ensure conformity of raw products and ingrediencies.

Food Design:

- Develop and create new food recipes tailored to specific customer groups.

- Predict customer acceptance of mainstream products.

Food Fraud:

- Validate product authenticity based on a molecular fingerprint.

- Identify stretched or adulterated products.

- Determine product origin and quality.

Exemplary

Analyses

Chocolate –

Sanitized customer example

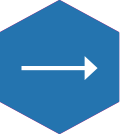

The flavor of chocolate is supposed to be made up of about 600 volatile organic compounds. This example shows a sanitized comparison of chocolates from different manufacturers.

The HaVoc sensory system not only allows to detect the single volatile organic compounds, it moreover enables to conduct a quantitative comparison highlighting e.g. the substitution of natural ingredients like Vanillin by more artificial replacements with similar flavor.

Coffee

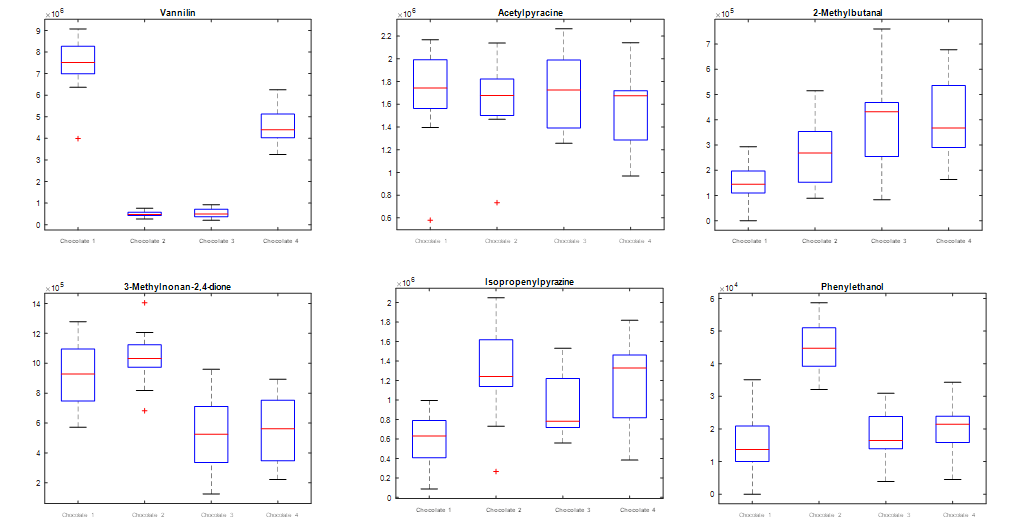

Coffee flavor is supposed to be very complex. While the smell of different coffee beans appear rather flat, the individual roasting procedures of the manufacturers lead to complex and very specific flavors.

Based on the analysis of the individual VOCs and the overall VOC fingerprints of different coffee samples, HaVoc is able to cluster, differentiate and identify different coffee roastings. The analysis furthermore revealed, that the specific coffee roasting procedures of the manufacturers are even more significant than the actual kind of coffee (espresso, coffee crema, etc.), as in an overall assessment, clusters are formed by producers rather than kind of coffee.

Product Qualities – Sanitized customer example

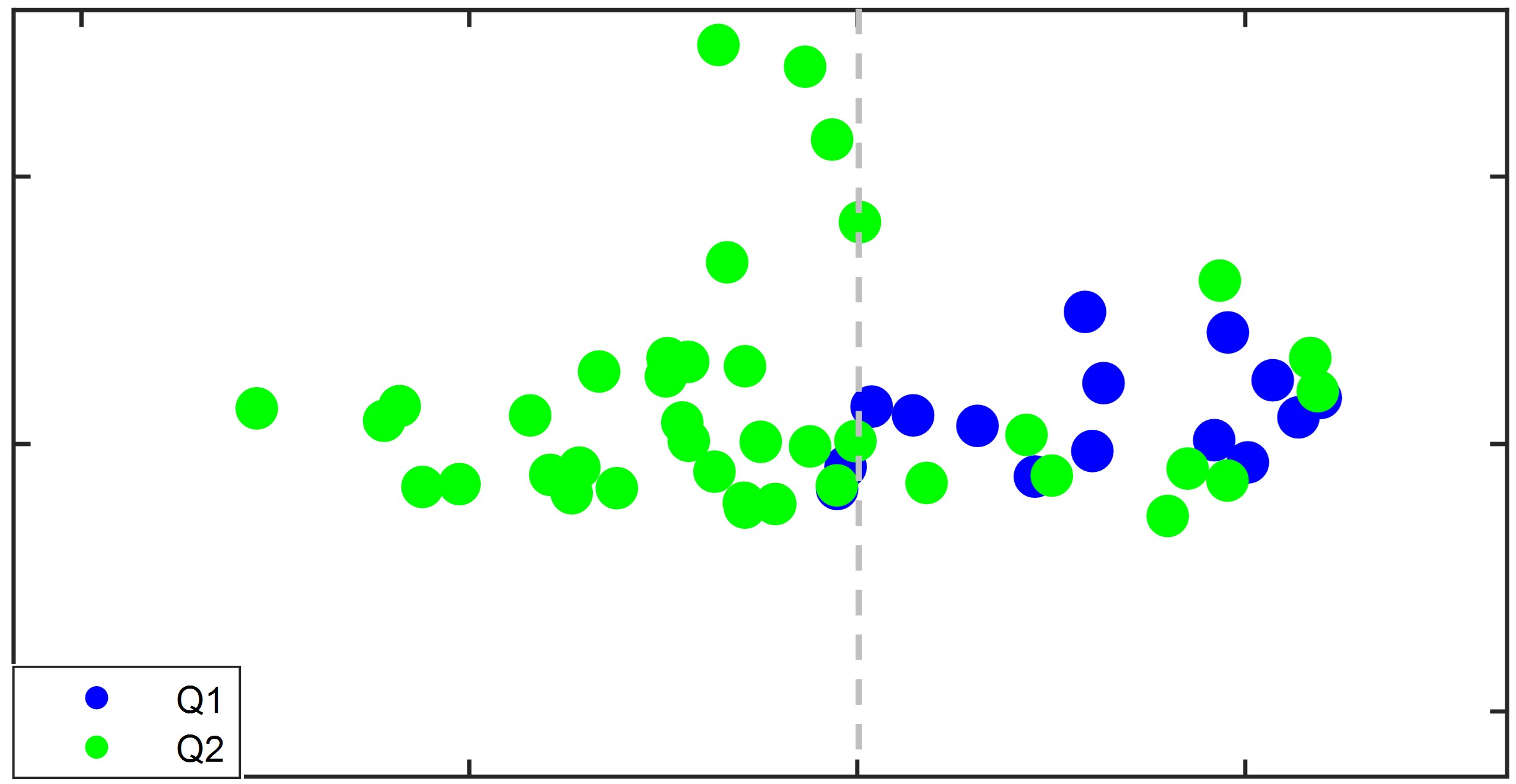

For the assessment of product quality in the food industry, human sensory panels are often the method of choice. However, the panel-based assessment has some drawbacks, especially regarding reliability and comparability of results.

This example shows a sanitized comparison of two different product qualities, which were pre-classified into quality grade #1 (Q1) and quality grade #2 (Q2) by the human sensory panel of the producing company.

Having a look at the algorithm-based clustering (HaVoc) while keeping the pre-classification in mind allows to determine a region clearly belonging to Q2 and another region where Q1 and Q2 are overlapping.

This clear separation of the two regions suggests some potential misclassification due to subjectivity of the human-sensory-panel.

Related Articles

Related App Note

Characterization of cherry-type flavorings

In this application note, we will introduce the capabilities of our new sensor system (HaVoc) for real-time analysis of volatile organic compounds (VOCs). This system is based on mass spectrometry and delivers real-time results of laboratory-grade quality.

Looking for a Laboratory Solution?

The HaVoc Sensory System is designed to revolutionize industrial analyses. If you are rather looking for a laboratory solution than an industrial one, discover our lab applications based on the SICRIT® ionization technology!